More than 84,000 dams exist in the US today. Some, but certainly not all, were built to capture the power of water. One of the best examples of a dam built to generate power from water is the Hoover Dam. It generates about 4 billion kilowatt hours of power annually to serve 1.3 million people in Nevada, Arizona and California.

But, could a dam built for other purposes – such as protecting agricultural lands or developed communities from floods – be retrofitted to create energy, too?

The answer comes from a small town in Moncure, North Carolina and its 30-year old Jordan Dam. Owned and operated by the Army Corps of Engineers, this dam was built to control floods. But with some innovative thinking, it is now generating energy, too. It now supplies power to communities in North and South Carolina.

The dam, which still provides flood control, first began generating hydroelectric power in January 2012. Engineering ingenuity in its design allows it to generate electricity 95% of the time.

We highlight this project this week as an innovative way for our country to make the most of our water, even the water that is held behind our nation’s dams. In this case, getting the most means retrofitting existing dams that didn’t include power generation as its original purpose to become new sources of energy now. Similar projects are in development in Virginia and being considered by the great states of North Carolina, Illinois and Montana.

To tell us the story of the Jordan Dam’s transformation to become an energy generator, we would like to introduce you to Paul Cyr, Project Engineer and Project Manager at Kleinschmidt, an engineering consulting firm. With their construction contractor, North Fork Electric, Inc, he led the Jordan Hydroelectric Project. It’s a first of its kind project and it’s making big waves for the industry. We welcome Paul:

– – –

How much power does the Jordan Hydroelectric Project produce?

The project produces 4,400 kilowatts of power, with an average annual generation estimated at 16,900 MWH, enough electric power for 1,700 homes. The renewable energy generated by the hydroelectric project annually displaces 17,500 tons of carbon dioxide emission that would be released if the power were generated using fossil fuels.

The project is located on the Haw River in Moncure, North Carolina. Why was this location chosen?

The project is located at an existing dam, thereby eliminating the need to construct a dam whose costs would probably have exceed $100 million dollars, assuming that environmental permits could have been obtained to allow the construction of a new dam. The dam was completed in 1982 for flood control, maintaining downstream water quality, and recreational purposes. The dam develops nearly 58 feet of gross head between the lake and the river and regulates a drainage basin with a mean flow in excess of 500 cubic feet per second (cfs), all of which resulted in favorable economics for development of the hydroelectric project.

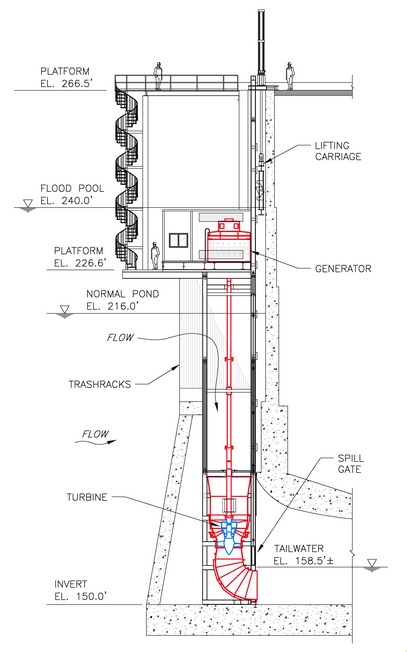

The project is the first facility of its kind in the country, using two vertical turbines installed on an intake tower at a U.S. Army Corps of Engineers flood control dam. Why was this innovative and unique design and placement chosen?

Powerhouses, hydroelectric or otherwise, usually consist of massive, standalone concrete structures that are fixed in place. For the Jordan Hydro project, the two hydroelectric turbines are located in individual, movable, structural steel enclosures (a.k.a. Power Modules) that weigh 115 tons and support the 62 tons of turbine-generator equipment, thereby eliminating the need for a standalone powerhouse. The Power Modules are located on the upstream side of the discharge tower. Under normal generating conditions, they set on the tower’s invert thereby eliminating the need to construct costly water retaining structures. Under flood conditions, the Power Modules are raised to release flow from beneath the modules. In addition, in the first 18 months of operation the hydro project has operated more than 1,500 hours at 90% of rated capacity with the Power Modules in the partially raised position and releasing a flow of 5,000 cfs beneath the modules. The ability to operate while in the partially raised position allows power to be generated 95% of the time.

The Jordan Hydroelectric Project is able to generate power 95% of the time without altering any of the flood control capabilities of the dam. Where does the power go and who benefits from it?

Power generated by the project is purchased by Progress Energy, a subsidiary of Duke Energy, and distributed to its North and South Carolina customers through the electric power grid.

What were some of the challenges the project team faced and how did they work to overcome them?

The three paramount challenges were: (1) removing the power modules from the discharge tower flow path quickly whenever flow releases were to exceed the total hydraulic capacity of the two power modules (3,100 cfs); (2) preventing the magnetic forces that develop when generating power from twisting and distorting the flexible and movable power modules; and (3) obtaining the Corps of Engineers approval of the project’s final design.

1) Each of the power modules can be lifted vertically 46 feet in 45 minutes by one person using a single 200-ton hydraulic cylinder to allow high flows to be discharged beneath the module.

2) The power modules are locked or anchored to the concrete discharge tower by six electrically operated horizontal screw jacks designed to stabilize the module and resist the 243,000 foot-pounds of torque generated by the generator and turbines 44,000 pounds of rotating mass. The jacks are retracted whenever the power modules must be raised.

3) Six design documents were submitted to the Corps for their review that demonstrated that the proposed project would not negatively impact on the safety or stability of the discharge tower or dam, nor would the project negatively affect the operational control of flows released from the dam.

This project has also been noted for its economical installed cost of around $2,300 per kW. How were you able to keep costs down with such a complex project?

The single factor to keeping the cost down was the lack of need to construct any water retaining structure or massive powerhouse. The cost of constructing a more conventional hydroelectric power project that included a standalone powerhouse with a dedicated intake tower and penstock easily could have exceeded $35 million rather than the $10 million for which this project was constructed.

The community of Moncure is small. Did the Jordan Hydroelectric Project generate a lot of public interest? How was project information communicated to the public?

Local public interest was along the lines of curiosity, as the public has walking access across the crest of the dam, and the power modules are located 200 feet upstream of the dam crest. The power modules can also be seen from a viewing platform at the Corp’s Visitor’s Center as seen in the image to the left. The Corps provided information on the hydro project on the Jordan Dam website, and the Corps and hydro project owner jointly provided informational signage at the dam. The North Carolina Small Hydro Generators Group visited the project, and North Carolina Public TV did a short informational documentary on the project.

The design features included in the Jordan Hydroelectric Project can be implemented at other dams. Have you heard of any interest in doing this at other locations?

Kleinschmidt is working with WV Hydro, the owner of the Jordan Hydro Project, to develop the Gathright Hydro Project in Virginia. The Gathright Project would be the big sister to the Jordan Project, generating 3.7 MW (18,200 MWH) under 140 feet of head; design is 30% complete. Kleinschmidt has also been approached by other parties interested in constructing hydro projects similar to Jordan at other dams owned by the Corps of Engineers (in North Carolina, Illinois, and Montana), all of which have construction costs of $8 to $12 million for 2 to 5 MW of generating capacity.

Are there locations that you believe would benefit from a hydroelectric project like this?

The Jordan Project did not use any proprietary or patented design, equipment, or operating systems; therefore, the concept can be adapted to any water storage/control dam containing a discharge tower used to control the release of flow. Whether the concept can be adapted depends on the geometry of the discharge tower’s upstream face and the amount of power that can be generated. Factors that could preclude the use of the concept at other dams are functions of economics: construction costs, MWHs generated, and sale price for the power.

What’s next for Kleinschmidt’s Hydro Engineering division? What are some other current projects that the public should know more about?

Providing engineering, regulatory, and environmental consulting services to the hydroelectric and other water related industries has been Kleinschmidt’s focus since 1966, and those services will continue to be our focus. We have worked on 1,400 hydro projects in the past five years and have offices nationwide, serving clients in 45 of the 50 states and in five Canadian provinces. Kleinschmidt has 140 personnel, and we are growing. We are recognized as specializing in “small” hydro projects, which are generally considered to be under 100 MW and under 300 feet of head. A number of the projects are, like the Jordan Project, considered to be non-conventional hydro projects or arrangements. That being said, Kleinschmidt is nearing completion of construction of a $440 million hydroelectric plant for PPL Holtwood in southeastern Pennsylvania. The plant is one of the largest new conventional hydro power projects east of the Mississippi that has been constructed in the last two decades. Kleinschmidt was retained to conduct a redevelopment study and assist PPL in all aspects of the license amendment, final engineering design, and construction process. The final design included the installation of a new 120′ by 240′ power station that contains two 65 MW, 23.5-foot diameter, vertical Kaplan turbines and associated equipment. The units are in the commissioning stage and are scheduled to be operational by the end of 2013. We are also 60% complete in the final design phase of two 11.8-MW hydroelectric plants to be constructed on existing Corps of Engineers locks and dams in Illinois.

– – –

We’re always excited to learn about cutting edge technology and projects finding ways to provide sustainable energy. We hope to see many more renewable energy projects follow in the innovative footsteps of the Jordan Hydroelectric Project.

Liz Faris, Account Manager

Collaborative Services, Inc.

Recent Comments